Tank Lining Service

Tank repair, lining and sealing upgrades with GRP

Existing tanks deteriorate. With exposure to chemicals, cycling and different temperatures, your tanks need to be protected to help you avoid problems.

Refurbishment as little as 20%

of the cost of replacement

If your tanks are already showing signs of wear, you don't have to replace them. A GRP lining refurbishment can cost as little as 20% of the cost of a tank replacement.

Durable tank linings and coatings for any conditions

A GRP lining is economical and hard-wearing – and can be customised using a variety of resins and additives to withstand almost any conditions and contents.

Whether you need to repair or line water tanks, chemical storage tanks, effluent tanks or even liquor tanks, we'll individually mix the right fibreglass tank lining for your needs.

Avoid the cost of a new tank

If you act fast, you can avoid replacing your tank. Thanks to our range of products – including epoxy compounds, polyester pastes and glass reinforced resins – we can fix most problems quickly.

We're experts at surface preparation, whatever your surface problem or structure of the base material, we can prepare it for the repairs you need.

Best of all, we'll normally have tank restoration completed within the week – and it will remain impact resistant and easy to clean for many years to come.

Health and Safety

Our commitment to health and safety is one of the primary reasons we have been entrusted to work on high risk establishments such as nuclear plants, chemical factories and railway stations.

Get your free tank survey today

Call 01206 798 798 now to arrange your free, no-obligation survey by one of our technical surveyors.

Hover over animation to hold

Tank problems. Don't replace it, we'll fix it with fibreglass lining...

Pipe connection corroded

and leaking

Problem: If your pipe connection is leaking, your tank isn't secure – with potentially dangerous results.

Solution: An industrial tank liner can cover the weak points surrounding your pipe connection and ensure it remains safe and watertight.

Tank roof corrosion

Tank roof corrosion

Problem: Tank lid is corroded.

Solution: We can repair from it from inside or outside the vessel as needed. If necessary, we can replace your tank roof entirely, so your tank will be back in action, fast.

Holes created by chemical corrosion

Holes created by chemical corrosion

Problem: Chemical attacks can lead to wall thinning and breaches, which risk contamination of the contents of your tank.

Solution: We will grit-blast the interior of your tank to create a suitable surface and then apply a GRP lining mixed to the right specifications for the tank's contents.

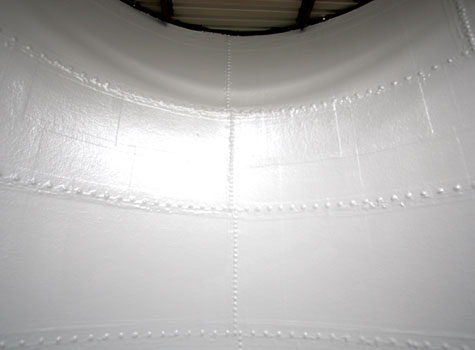

Failed joints causing leaks

Failed joints causing leaks

and corrosion

Problem: Sectional tanks can be prone to leaks in the joints.

Solution: We will specify the right industrial linings to stop any leaks keeping your tank leak-free.

Case Studies

Tank Lining, Scotland

Sui Generis were called in to save a leaking sprinkler tank in historic Aberdeenshire in the North East of Scotland...

View case study.

Sectional Tank Lining

GRP refurbishment of a corroded sectional tank used for storing pigments...

View case study.

Potable Water Tank

GRP lining given to a leaky GRP potable water tank in a hard to access location...

View case study.

Lining Refurbishment

GRP lining gives an industrial fire sprinkler tank at least another 20 years of life...

View case study.

Concrete Water Tank

Repairs were made to cracked areas of concrete water storage tanks with a GRP lining...

View case study.

Filtered Water Tank

GRP lining refurbishment of a semi-submerged cooling tower basin...

View case study.

Potable Water Tank

Application of a fibreglass lining to a Hospital potable water storage tank...

View case study.

Wastewater Tank

Repair and GRP Lining for a food preparation factory wastewater treatment tank...

View case study.

Effluent Tank Lining

GRP Lining and repair to an underground effluent tank, damaged due to pressure from the water table....

View case study.

Tank variations that benefit from a Sui Generis fibreglass lining:

Sectional water tanks

Process water tanks

Concrete process tanks

Cylindrical chemical tanks

Cylindrical chemical fertilizer tanks

Cylindrical sectional effluent tanks

Concrete effluent tanks

Cylindrical fuel tanks

5 good reasons to choose Sui Generis fibreglass linings for your tanks...

- Savings – no need to replace your tank

- Durability – 20+ year lifespan

- Seamless – no weak joins

- Flexibility – linings mixed to almost any specification

- Corrosion-proof – chemical resistant

Tank lining repair guide

Industrial tanks house a variety of liquids from chemicals to effluent – but because most of them are constructed from steel and concrete, they are also subject to rust, corrosion and erosion.

Over time, a tank's original structure can deteriorate, causing problems such as cracks, leaks and failed joints – which could lead to dangerous spills...

That's where a tank lining comes in. A GRP lining is economical, versatile and hard-wearing – effectively creating a tank within a tank.

It provides a stable, chemical- and impact-resistant structure within your existing tank, extending its useful life by more than 20 years.

By choosing a GRP lining instead of replacing your damaged tank, you can also save up to 80% on your costs.

What kinds of tanks can be repaired?

Fibreglass tank linings from Sui Generis can increase the longevity of tanks constructed from any material – including concrete, steel and polypropylene.

Our industrial linings can contain most kinds of liquids, from toxic or corrosive chemicals right through to aviation fuel and alcohol. Some of the tanks we can line for you include:

- Sectional water tanks

- Process water tanks

- Portable water tanks

- Liquor tanks

- Effluent tanks

- Water treatment tanks

- Sprinkler tanks

- Diesel tanks

- Fuel oil tanks

- Gas oil tanks

- Fertilizer tanks

- Chemical storage tanks

- Offshore applications.

Why choose fibreglass tank repair?

Because its tough, hard-wearing and handles normal structural movement well – which is especially important for concrete structures.

A GRP tank lining is also thicker than an ordinary epoxy coating. Where the latter is only a 0.5mm barrier, a fibreglass tank lining is between 2mm and 6mm thick.

It can also be used to line over cracks, corrosion and thinning tank walls – giving your tank a new lease on life and you lasting peace of mind.

Moreover, each lining is individually mixed using resins and additives to meet the needs of your tank and what its contents.

Are there other benefits to GRP tank linings?

Yes. A GRP lining for your tank will also be:

- Corrosion Proof

- Chemical resistant

- Leak free

- Impact resistant

- Flexible

Can you give me advice about my tanks?

We're ready and waiting to help you repair and restore your tanks and save you the expense of having to replace them.

Just call us on 01206 798 798 today and ask for a free site inspection by one of our experts to find out everything you need to do to get your tanks back in perfect working order.

Environment Agency Guidelines

What businesses and organisations should do at work to avoid pollution incidents, including the permissions you need to dispose of waste:

Pollution prevention for businesses

Storing materials, products and waste

Installation of underground

storage tanks

Decommission of underground

storage tanks

Oil storage regulations and safety

Oil storage regulations for businesses

Oil storage secondary containment

What our customers say about us...

What our customers say about us...

We're committed to the providing the best quality products and service,

here's what our customers say about us...

Hover over area to hold. All our reviews are independently verified.

Sui Generis: The market leader in GRP fibreglass lining

Quality guarantee

Quality guarantee

Our highly competitive work gives you the best quality results every time – every one of our operatives is highly skilled, well trained and takes exceptional pride in what they do. With Sui Generis, you can rely on effective, long-lasting work.

Compliance and accreditations

Compliance and accreditations

When you choose Sui Generis to undertake work on your behalf, it always complies with and exceeds the standards required by relevant legislation. We always advise you what the regulations require before we start.

Our health & safety promise

Our health & safety promise

We take your safety seriously, and that of all our people, whether we're at a small factory or a nuclear plant. We always adhere to stringent health and safety procedures at every stage – and comply with your own Heath and Safety policies.