Bund Lining Service

Bund lining, repair & sealing upgrades with GRP

Your bunds are exposed to tough conditions – but continued exposure to oils, chemicals and other liquids can make them crack, corrode, leak or become contaminated.

Does your bund need lining?

Bunds that aren't leak-free or safe can lead to expensive site damage, and if they breach Environment Agency pollution guidelines you could be fined tens of thousands of pounds.

Economical, durable fibreglass bund linings

Don't let this happen. Solve the problem for the long term and line your bunds with a fibreglass bund lining.

Fibreglass is long lasting and copes well with normal structural movement – and because it's impact resistant and easy to clean it'll remain maintenance free for many years to come.

Avoid expensive bund rebuilds

A fibreglass bund lining, also known as GRP lining, can mean the difference between a cost-effective bund repair and an expensive bund replacement.

We'll grit blast your bund and make any necessary repairs, upgrades or extensions. Next, we'll line your bund to create a long-lasting alternative to a complete bund rebuild.

Best of all, we'll normally have the job done within the week – so inconvenience is kept to a minimum.

Health and Safety

Our commitment to health and safety is one of the primary reasons we have been entrusted to work on high risk establishments such as nuclear plants, chemical factories and railway stations.

Get your free bund survey today

Call 01206 798 798 now to arrange your free, no-obligation survey by a technical surveyor.

Hover over animation to hold

Bund problems. Don't replace it, we'll fix it with fibreglass lining...

Leaking bund

Leaking bund

Problem: If you see plants growing in the joins of a bund, it's not secure. When liquid fills the bund, it will leak out of the cracks the weeds have taken root in.

Solution: A fibreglass bund lining will cover these weak points and make the bund safe once again.

Damaged bund wall

Damaged bund wall

Problem: Big cracks mean you've got serious safety issues on your hands. If a corrosive or toxic liquid filled this bund, it would gush out through the wall – fast.

Solution: Repairs to the concrete combined with a GRP lining would soon put this bund back in action.

Contaminated bund wall

Contaminated bund wall

Problem: When oils or acids drip or spill into a concrete bund, they penetrate any unprotected concrete and contaminate it.

Solution: Fibreglass bund linings are durable, washable and provide better and longer-lasting protection than epoxy coatings.

Unsealed bund pipe

Unsealed bund pipe

Problem: If you have an older bund with one or more pipes passing through the walls, the join can be a leak waiting to happen.

Solution: A fibreglass reinforced lining, giving this particular weak point substantial protection.

Industrial Bund Lining Case Studies

Acid Resistant Lining

GRP lining to existing and new sulphuric acid storage tank bunds, for a waste management company...

View case study.

Oil Tank Bund Lining

GRP bund linings create a long-lasting oil-tight solution for aviation fuel, diesel and de-icer tank bunded areas...

View case study.

Oil Resistant Lining

How we installed an oil resistant GRP lining to tank storage bunded areas for an upmarket snacks manufacturer...

View case study.

Concrete Bund Lining

GRP lining to a concrete tank bund, enclosing all internal walls, floor, gullies and sumps....

View case study.

Chemical Silo Bund

GRP lining was created for a new internal chemical storage silos bunded area to maximise the bund life...

View case study.

Waste Water Bund

GRP bund lining for new waste water bund, salt tank, acid silo bund, and chemical loading pit areas...

View case study.

Flammable Liquid Storage Bund Lining

A GRP lining is the only practical solution for sealing in complicated structures, enclosing all internal walls, gullies and sumps...

View case study.

Acid Dosing Room GRP Lining

GRP lining applied to a concrete and block bund floor and walls, acid dosing room for a water and waste water management facility...

View case study.

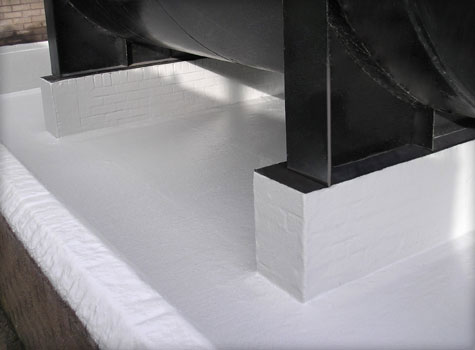

Generator Bund

Wall and Floor Lining

GRP lining of a generator bund, including internal concrete trench runs, carefully working around the complicated pipe and cable areas...

View case study.

Storage Tank Bunds and Pipe Area Lining

GRP lining of storage tank bunds and pipe areas for a food preparation factory....

View case study.

Bund Water Control Pumping Unit

An automatic pumping system that safely pumps water out of a bund... Bund Water Control Unit

Bund Access Platforms

Custom made GRP platforms create safe walkways for bunds, doorways, stairs and inspection platforms...

View access platforms

5 good reasons to choose Sui Generis fibreglass bund linings...

- Economy – long term savings

- Quality – 20+ year lifespan

- Safety – installed by experts

- Speed – in place in a week

- Service – 90% repeat custom rate

Bund Lining - Frequently Asked Questions

What is a Sui Generis Fibreglass Bund Lining System?

It literally involves building a new bund within the existing structure.

Following the required preparation to remove foreign matter, our four-coat lining system is hand applied to the existing structure. The finished lining has its own structural strength with a nominal thickness of 3mm.

Our Fibreglass Bund Linings are corrosion resistant, have excellent impact resistancy and are flexible enough to deal with structural movement.

My tank bund is leaking at the wall joints, how does a Fibreglass Lining

overcome this problem?

Our Fibreglass Lining has no joints or seams and therefore creates a complete seal making your bund impermeable to both water and the storage vessels contents.

Is a bund Fibreglass Lining more expensive than other alternatives?

Possibly the initial cost will be, however, the long term benefits are obvious as it is corrosion resistant, will not flake has an indefinite life expectancy.

But unlike other materials, there are no annual up-keep costs such as painting or treating. You're unlikely to have to worry about replacing it again.

Will the Fibreglass Lining need any maintenance?

No, just good housekeeping and the occasional clean to wash off dirt.

Do you use Sub-Contractors to carry out the installation?

Absolutely not, all the installation is carried out by our trained technicians.

How do you know that your Fibreglass Lining is suitable for my storage requirements?

Following the advice of our Chemist, the type of resins used for your fibreglass Lining is determined by the substance you are looking to contain and the operating environment of your bund.

Our linings can even be made suitable for some of the most aggressive chemicals and chemical mixes.

What kinds of liquids can a bund lining contain?

Our fibreglass bund linings contain most kinds of liquids, from toxic and corrosive solutions right through to aviation fuel or dairy products. These are just some of the bunds we can line for you:

- Sodium Hypochlorite bund

- Sodium Hydroxide bund

- Urea bund

- Sulphuric Acid bund

- Transformer Oil bund

- Gas Oil bund

- Diesel Oil bund

- Vegetable Oil bund

- Acetic Acid bund

- Sewerage bund

- Chlorinated Water bund

- Nitric Acid bund

- Aluminium Sulphate bund

- Hydrochloric Acid bund

- Ethylene Glycol bund

- Alcohols bund

- Vinegar bund

- Ethanol bund

What about the condition of the existing bund walls and floor?

Because it is reinforced and has its own structural integrity, of some substance, our Fibreglass Bund Lining is not wholly reliant on the existing substrate to remain sound.

If the substrate surface becomes flaky or crumbly any coating will lose its adhesion. With a Fibreglass Lining this is totally acceptable, even with massive de-lamination up to 80 or 90%.

Do you have to wait for ideal weather conditions before you can line my bund?

No, whilst most lining or coating systems demand all but perfect conditions and surfaces when being applied a Fibreglass lining system is very 'forgiving' and has a much wider tolerance to adverse conditions without its long-term value being undermined.

Consequently, a Fibreglass Lining system can usually be installed all year round to meet your requirements and not that of the weather.

Will you keep my site tidy?

It will be necessary to have materials on site but our operatives are fully aware of the importance of good housekeeping and all materials will be safely stored.

Our work areas will be left clean and tidy when we depart from site and the only evidence of our visit will be our Fibreglass Lining.

What are your credentials for carrying out my tank bund lining?

We have been carrying out Fibreglass Linings for over 20 years, during this time we have been entrusted with carrying out work on high risk establishments such as nuclear plants, chemical factories and railway stations.

The biggest endorsement we can provide is the comments of customers who have experienced us at first hand. Customer Testimonials.

Do your bund linings and repairs conform to regulations?

Yes. Bunds and bund repairs have to conform to stringent pollution control regulations, which are there to ensure secondary containment is of sufficient size, oil-tight, contains no direct outlet and has no pipework passing through it if avoidable.

Our bund repairs and upgrades all comply with current Pollution Prevention Guidelines (PPG2) and SEPA (Scottish Environment Protection Agency) regulations.

What quality accreditations do you have?

ISO 9001:2015 Quality Management System.

Having first achieved ISO 9001 accreditation in 2002 our Quality Management System and associated procedures are now firmly ingrained into our everyday practices, this combined with the fact that many of our site operatives have been with us for over a decade means that stringent quality control has become second nature to us ensuring that you will be left with a product of the highest quality.

ISO 14001:2015 Environmental Management System.

Every employee is committed to working to the instruction framed within the company quality and environmental management system and ensuring that they are fully implemented. This includes the need to maintain clear lines of communication with our customers and between ourselves at all times.

Can you give me advice about my tank bunds?

We'd be delighted to help you repair or line your problem bunds.

Just call us on 01206 798 798 today and we'll arrange a free site inspection to give you all the information you need to get your bunds back in perfect working order.

Environment Agency Guidelines

What businesses and organisations should do at work to avoid pollution incidents, including the permissions you need to dispose of waste:

Pollution prevention for businesses

Storing materials, products and waste

Installation of underground

storage tanks

Decommission of underground

storage tanks

Oil storage regulations and safety

Oil storage regulations for businesses

Oil storage secondary containment

What our customers say about us...

What our customers say about us...

We're committed to the providing the best quality products and service,

here's what our customers say about us...

Hover over area to hold. All our reviews are independently verified.

Sui Generis: The market leader in GRP fibreglass lining

Quality guarantee

Quality guarantee

Our highly competitive work gives you the best quality results every time – every one of our operatives is highly skilled, well trained and takes exceptional pride in what they do. With Sui Generis, you can rely on effective, long-lasting work.

Compliance and accreditations

Compliance and accreditations

When you choose Sui Generis to undertake work on your behalf, it always complies with and exceeds the standards required by relevant legislation. We always advise you what the regulations require before we start.

Our health & safety promise

Our health & safety promise

We take your safety seriously, and that of all our people, whether we're at a small factory or a nuclear plant. We always adhere to stringent health and safety procedures at every stage – and comply with your own Heath and Safety policies.