Case Study: Fibreglass Gully Lining

The client

When you make essential interconnect components for the military, aerospace and industrial markets, your facilities need to be in top shape. One of our clients knew this, but faced a problem.

The problem – a leaking gully

A leaking gully posed a serious environmental threat if chemical runoff in the gully leaked into the concrete and earth below.

Having previously worked with Sui Generis to line their bunds, our client knew exactly who to call to effect a high quality repair and sealing of their gully with minimum downtime.

The solution – a fibreglass lining

About 20m long, the gully or pit needs to collect and channel runoff from chemical tanks used for dipping components.

But as it was tiled, corroded grouting meant the surface was quickly coming apart.

We recommended completely lining the floor and walls of the gully with GRP fibreglass for a strong, chemical-resistant coating.

Fast and efficient gully lining

A three-man Sui Generis team took just four days to complete the repair and line the gully. And because the work was undertaken over a bank holiday weekend, disruption was kept to a minimum.

Now that the work is complete, the gully can handle chemical runoff without wear or corrosion – for many years to come.

Hover over animation to hold

Fibreglass gully lining, from preparation to completion

Special surface cleaning

Special surface cleaning

Chemicals running through the gully had corroded the grouting between the tiles, causing many to become displaced.

Sui Generis first had to carefully clean the affected area and remove the loose tiles before the repair could begin.

Gully preparation

Gully preparation

Because the walls and floor of the gully were tiled and it was classed as a sensitive area, grit blasting would have been unsuitable. So we applied a special primer to the surface and fitted pre-made fibreglass sheets where tiles had been removed to ensure a flat, level surface.

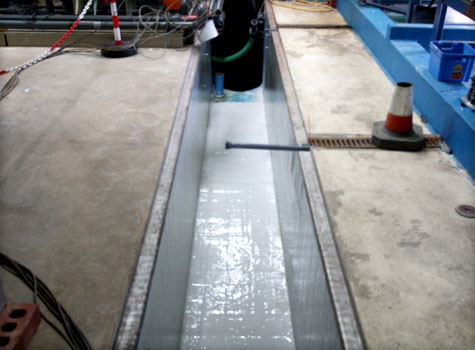

Applying the fibreglass lining

Applying the fibreglass lining

An etching primer was then used on the walls and chemical-resistant GRP fibreglass was applied to both the walls and floor, coating the entire length of the gully. This provides a long-lasting, impact resistant channel where chemical runoff can travel safely.

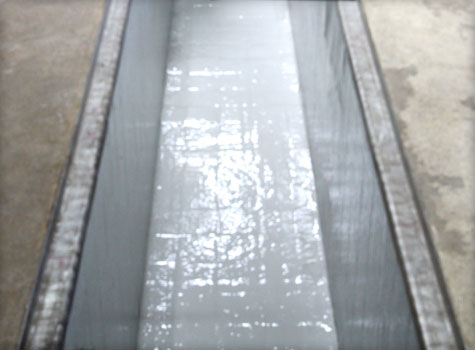

A perfect finish

A perfect finish

For the perfect finish, we added a final resin top coat to make sure every surface was water-tight. Then we reinstalled all the pipework that had to be removed in order to perform the pit repair, insuring as little delay as possible for production.

Sui Generis: The market leader in GRP fibreglass lining

Quality guarantee

Quality guarantee

Our highly competitive work gives you the best quality results every time – every one of our operatives is highly skilled, well trained and takes exceptional pride in what they do. With Sui Generis, you can rely on effective, long-lasting work.

Compliance and accreditations

Compliance and accreditations

When you choose Sui Generis to undertake work on your behalf, it always complies with and exceeds the standards required by relevant legislation. We always advise you what the regulations require before we start.

Our health & safety promise

Our health & safety promise

We take your safety seriously, and that of all our people, whether we're at a small factory or a nuclear plant. We always adhere to stringent health and safety procedures at every stage – and comply with your own Heath and Safety policies.