Case Study: Water Tank Lining and Repair

Sprinkler Tank Lining

When a number of minor leaks were discovered in an industrial fire sprinkler storage tank, Sui Generis were called in to carry out a permanent repair by giving the cylindrical tank a watertight GRP (fibreglass) lining. The whole installation was completed within a week, leaving the customer with a tank free from leaks and corrosion for many years to come.

Corrosion

The manufacturer's water storage tank, which supplied a factory-wide sprinkler system, had been found to be suffering from severe corrosion at the water level, resulting in several small leaks. Not only did this constitute a potential threat to the factory in the event of a fire, it meant it would fail a forthcoming safety inspection and lead to higher insurance costs.

Recommendation

The client's insurers recommended that Sui Generis should be called in to carry out a full and long-lasting repair to the tank. After a free survey, Sui Generis recommended applying a strong, flexible GRP lining that would repair the corroded areas and ensure the tank was completely watertight.

Installation

The Sui Generis team first extracted the sludge that had accumulated at the bottom of the tank, and grit-blasted the internal surfaces to remove scale and rust. As the band of corrosion at the water level was severe, they removed all these damaged areas and then rebuilt the upper part of the tank with GRP. They applied four layers on the inside and an extra one outside, continuing above the corroded area to provide extra strength.

The industrial GRP lining was applied to the whole of the tank interior to ensure every part was sealed. The lining was then sprayed with a light grey finish. The whole process was completed with minimal disruption within a week and for a fraction of the cost of a new tank.

FREE site survey

Call our specialist team to discuss your requirements, quote and get a FREE site survey: 01206 798 798.

Industrial Tank Lining Service

How we lined the leaking water tank…

The water tank is grit-blasted

The water tank is grit-blasted

After the water was drained from the tank and the remaining sludge removed, the Sui Generis team grit-blasted the interior to prepare the surface for the application of the fibreglass lining.

Applying the fibreglass lining

Applying the fibreglass lining

Next, all bolted areas within the tank were given a layer of fibreglass first. This acts as an extra layer of protection to prevent sharp metal breaking through. After this, the whole tank was given a complete layer of fibreglass while the low-level holes were given a double layer for extra strength.

Rebuilding the corroded area

Rebuilding the corroded area

Because a band of severe corrosion had appeared at the water level line, the Sui Generis team removed the damaged areas and then rebuilt the upper part of the tank with fibreglass – four layers on the inside and an extra one outside, continuing above the corroded area for 150mm for extra strength.

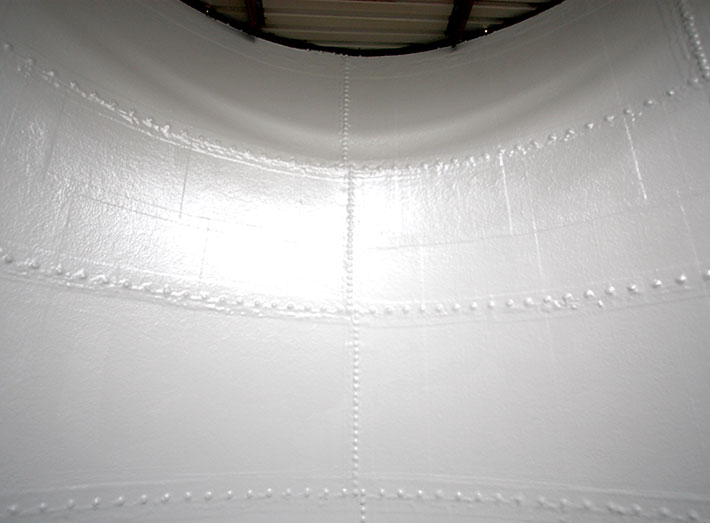

A tidy, professional finish

A tidy, professional finish

With the lining completed, the interior of the tank was resin-coated and flow-coated and an additional fibreglass coating was applied to the exterior of the tank to help it look neat and tidy. A light grey galvanized finish then completed the water tank refurbishment.

-

"I would not hesitate in recommending Sui Generis to any other company for this type of work and commend all three operators for their conduct and hard work."

-

K Lunn,

Fibreglass lining to Sprinkler tank

Read more testimonials

Sui Generis: The market leader in GRP (fibreglass) tank lining

Quality guarantee

Quality guarantee

Our highly competitive work gives you the best quality results every time – every one of our operatives is highly skilled, well trained and takes exceptional pride in what they do. With Sui Generis, you can rely on effective, long-lasting work.

Compliance and accreditations

Compliance and accreditations

When you choose Sui Generis to undertake work on your behalf, it always complies with and exceeds the standards required by relevant legislation. We always advise you what the regulations require before we start.

Our health & safety promise

Our health & safety promise

We take your safety seriously, and that of all our people, whether we're at a small factory or a nuclear plant. We always adhere to stringent health and safety procedures at every stage – and comply with your own Heath and Safety policies.