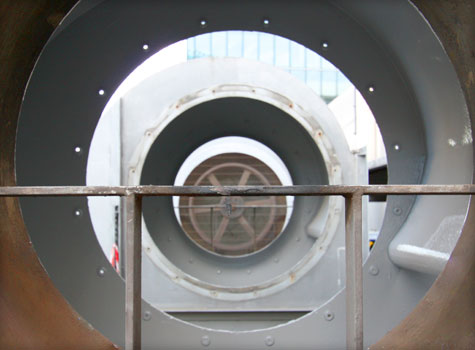

Cooling Tower Lining

Cooling tower lining, repair and upgrades with GRP

If cooling towers aren't properly coated, they will begin to fail. If they're made of stainless steel, they can begin to leak at the joints. If they're made of mild steel, they can corrode too – and both can provide a breeding ground for legionella.

Cooling tower ponds take particular punishment, and less durable coatings like epoxy are prone to fail. A fibreglass lining eliminates the problem, creating a 'pond within a pond' that can last for decades.

Safe, long-lasting fibreglass linings

GRP cooling tower linings are safe and long-lasting, and can remain maintenance free for many years.

A GRP lining seals and prevents leaks at the joints between sections, handles normal structural movement well and is a cost-effective way of lining your cooling towers to the highest industrial standards.

Protect staff from harmful bacteria

The resins we use for lining your cooling towers meet BS:6920 standards and have been subjected to a range of microbiological growth tests to ensure that our GRP linings do not support the growth of harmful bacteria, including Legionella Pneumophila (the source of Legionnaires' disease).

We'll prepare the internal surfaces of your cooling towers and then apply a fibreglass lining that will keep them in perfect condition for years to come – on time and on budget.

Health and Safety

Our commitment to health and safety is one of the primary reasons we have been entrusted to work on high risk establishments such as nuclear plants, chemical factories and railway stations.

Get your free survey today

Call 01206 798 798 now to arrange your free, no-obligation survey by one of our technical surveyors.

Hover over animation to hold

Put these problems behind you with a fibreglass lining for your cooling towers...

Contamination & legionela

Our GRP liner has been tested to ensure it does not support microbiological growth. So when you ask us to line a cooling tower, we help maintain a safe cooling system – which reduces the risk of infections such as Legionnaires' disease.

Corrosion & leaks

Scale, corrosion and leaks – problems which can in turn lead to the deterioration of your towers, higher costs and unreliable cooling. But if you ask us to coat the inside of your cooling towers with our fibreglass lining, they'll be in top condition and maintenance-free for years to come.

Interior deterioration

Many factors can cause the lining of your cooling towers to deteriorate over time – which can lead to further problems down the road. Just ask us to apply our fibreglass lining for a tougher and longer-lasting internal coating that will weather even the toughest conditions.

Insecure structure

Over time, the mastic between the joints of the tower can fail, causing fissures and leaks from these areas – which can prove disastrous. Fortunately, our fibreglass lining copes well with normal structural movement and because we build a now sweamless 'pond' within the old, there are no joints to leak.

5 good reasons to choose Sui Generis cooling tower fibreglass linings...

- Economy – long-term savings

- Quality – 20+ year lifespan

- Safety – reduce the risk of harmful bacteria

- Precision – installed by experts

- Service – 90% repeat custom rate

Cooling tower repair guide

Cooling towers ensure the quality and temperature of air circulating throughout a large building. They draw in air, cool it using water, and then distribute it through a building via a network of pipes. But because cooling towers components are made of metal, they are at threat of corrosion...

Over time, original linings can wear away, leaving the metal exposed to water. This can result in a range of problems including the growth of harmful microbiological organisms like legionella that can be spread through the ventilation system of a building.

This can make cooling systems unsafe – and even illegal.

However, it's simple to avoid this problem by coating the inside of your cooling towers with a fibreglass lining. This won't react to water, doesn't encourage the growth of unwanted bacteria and can last for decades.

What can cause a cooling tower to fail?

In mild steel cooling towers, the most common threat is corrosion due to the failure of an inadequate coating. Stainless steel towers can also fail at the joins.

Unlike fibreglass, non-approved paint such as an epoxy coating or bitumen doesn't have the strength, longevity or chemical resistance to keep your cooling towers safe and secure over time.

Both corrosion and joint failure can result in expensive replacement costs and result in micro-bacterial growth that can prove harmful to to staff working in the buildings serviced by the cooling towers.

Why use fibreglass to line a cooling tower?

A fibreglass lining is the best way to protect your cooling towers and ensure they last longer and require less maintenance. It also has the added advantages of being:

- Corrosion Proof

- Micro bacteria resistant

- Leak free

- Flexible

Do your cooling tower linings and repairs meet regulations?

Yes. Our GRP linings are approved by the Water Regulations Advisory Scheme as well as the Drinking Water Inspectorate – each of which has independently tested out linking to ensure it's resistant to the growth of harmful bacteria and safe to use in cooling towers.

Ask us for more details – we've got a free and helpful advice guide about about cooling tower repair.

Can you give me advice about my cooling towers?

We'd be happy to give you all the advice you need to ensure your cooling towers are safe and secure for years to come.

Just call us on 01206 798 798 today and we'll arrange a free site inspection to help you get your cooling towers operating exactly as they were designed to.

What our customers say about us...

What our customers say about us...

We're committed to the providing the best quality products and service,

here's what our customers say about us...

Hover over area to hold. All our reviews are independently verified.

Sui Generis: The market leader in GRP fibreglass lining

Quality guarantee

Quality guarantee

Our highly competitive work gives you the best quality results every time – every one of our operatives is highly skilled, well trained and takes exceptional pride in what they do. With Sui Generis, you can rely on effective, long-lasting work.

Compliance and accreditations

Compliance and accreditations

When you choose Sui Generis to undertake work on your behalf, it always complies with and exceeds the standards required by relevant legislation. We always advise you what the regulations require before we start.

Our health & safety promise

Our health & safety promise

We take your safety seriously, and that of all our people, whether we're at a small factory or a nuclear plant. We always adhere to stringent health and safety procedures at every stage – and comply with your own Heath and Safety policies.