Case Study: GRP Lining of Generator Bund Wall and Floors, Trench Runs, Pipe and Cable Areas

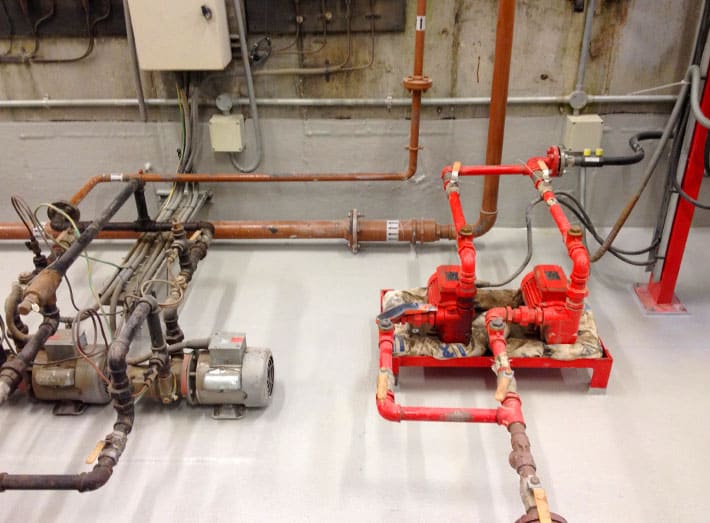

All areas of this generator wall and floor bund were GRP lined, including internal concrete trench runs, carefully working around the complicated pipe and cable areas.

Fibreglass matting was moulded to the internal surfaces encapsulating tank plinths, upstands and pedestals.

The generator bund GRP lining was completed with minimum disruption.

A low cost, low disruption, low maintenance, long life bund solution.

1. Generator bund: fibreglass matting moulds to the internal surfaces encapsulating tank plinths, upstands and pedestals.

Tank bund lining solutions

We offer a high quality bund lining service to produce a simple, long term cost effective solution to your spill containment, protection and corrosion problems.

2. Generator bund before: pipe and cables in the bunded area.

Get a FREE site survey today

Our technical surveyors have years of experience within the industry and are experts in fibreglass lining.

A free site survey will provide you with recommendations for the future use of your tank bund spill containment area.

Call our specialist team to discuss your requirements, quote and get a FREE site survey: 01206 798 798.

3. Generator bund: completed GRP lined area.

4. Generator bund before and after: tank wall and floor areas GRP lined.

5. Generator bund before and after: tank wall and floor area with GRP lining.

6. Generator bund before and after: internal concrete trench runs, with GRP lining.