Bespoke GRP and FRP Composite Components

Sui Generis – By Name and By Nature

We specialise in the design and manufacture of custom GRP (Glass Reinforced Polymer) and FRP (Fibre Reinforced Polymer) components, built to meet the unique requirements of our clients across the architectural, automotive, and industrial sectors.

True to our name — Sui Generis, meaning “of its own kind” — we thrive on producing one-of-a-kind solutions. From large-scale production runs to highly specialised, one-off commissions, we turn complex ideas into expertly engineered, finished products.

Whether you’re working on a detailed architectural feature, a durable industrial housing, or something completely out of the ordinary, we offer a full-service solution — from design development to precision manufacturing and final finishing.

Custom Engineered GRP Components – Built to Your Specification

Whether you need a single one-off item or a regular supply of custom-manufactured parts, Sui Generis can deliver custom engineered GRP and FRP composite components tailored precisely to your design, performance, and aesthetic requirements.

Our team has produced everything from acid-resistant battery enclosures to giant burger shapes for mobile catering vans, and even oversized props and scenic elements for film and television sets. No matter how imaginative or industrial your brief, we can bring it to life in virtually any shape, size, colour, or finish.

With excellent strength-to-weight properties, outstanding chemical resistance, and low maintenance requirements, GRP and FRP components offer a durable and cost-effective alternative to traditional materials — while allowing for creative freedom and complex geometry.

If you can visualise it, we can mould it. Let us support your next project with a custom FRP solution engineered for performance and built to last.

What’s the Difference Between GRP and FRP?

GRP (Glass Reinforced Plastic) is a specific type of FRP (Fibre Reinforced Polymer) that uses glass fibres as the reinforcing material. While GRP remains a popular, high-performance solution for many industrial applications due to its strength, durability and cost-effectiveness, the broader term FRP encompasses a wider variety of fibre reinforcements—including sustainable alternatives such as flax or hemp.

We offer both GRP and FRP solutions to meet a range of technical and performance requirements. As we continue to innovate, we are exploring and adopting more sustainable fibre technologies within our FRP range to help reduce environmental impact without compromising quality or structural integrity.

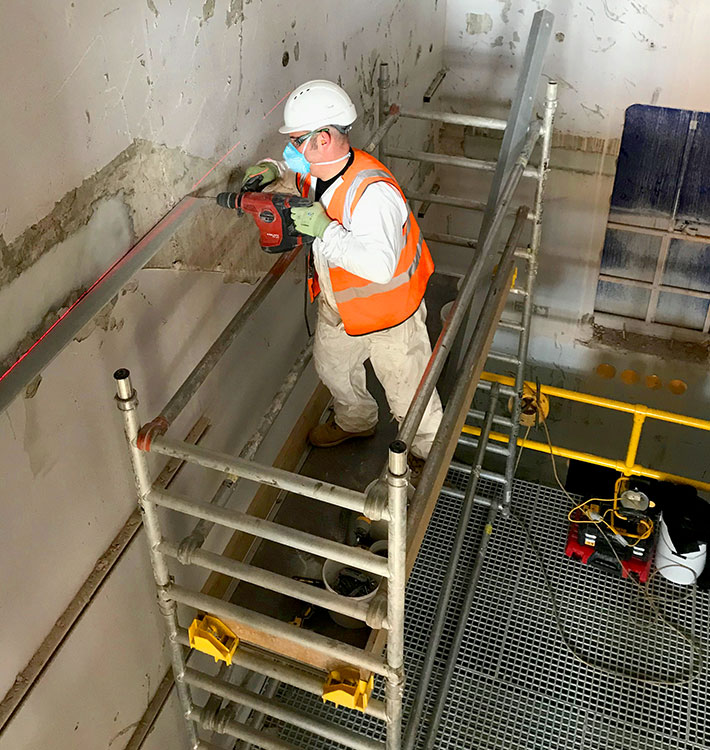

The FLOW bridge reimagines traditional construction by using a modular system made from FRP composites — a lightweight, high-strength material reinforced with glass, carbon, or aramid fibres. Sui Generis manufactured and supplied the complete bridge structure, including walkway modules, stair inlays, and sidings.

The modularised system also allows for most of the materials to be manufactured off-site, reducing the pressure on installation teams and disruption of passenger services and track closures.

Installation of the footbridge can be done in half the amount of time it would take for a traditional in-situ produced steel structure.

Composites are up to 70% lighter than steel and have a high strength-to-weight ratio. This considerably reduces transportation and installation costs, making FRP an ideal solution for a rail footbridge.

Custom made GRP composite components

We were delighted when the contractor assigned with the task of fitting out Barclays Bank branch approached us to produce GRP outer shells for a concierge desk and halos.

For this large format sign for exterior use GRP composites was perfect. Long lasting, maintenance free, weather risistant solution, and looks great when installed on London residential area.

Sui Generis specialise in making custom GRP storage and equipment boxes to suit specific customer requirements.

From commercial fleets to agricultural and military vehicles, we can create the mouldings you need — and supply your parts in a base colour or high quality gel finish ready to fit straight onto your vehicles.

Custom Engineered GRP and FRP Composite Components – A Sui Generis Guide

GRP and Fibre Reinforced Polymer (FRP) are incredibly adaptable composite materials that can be moulded into almost any shape, making it ideal for a vast range of industrial, architectural, and commercial applications.

Its corrosion and chemical resistance makes GRP and FRP the perfect choice for manufacturing storage tanks, tank lids, and protective covers for pits, machinery, and process areas. Lightweight yet exceptionally strong, it’s also well suited to automotive components, and can be finished to replicate traditional materials like stone, ceramic, or metal — ideal for architectural detailing and heritage restoration.

Increasingly, designers are turning to FRP for modern, colourful furniture in office, retail, and outdoor environments, thanks to its formability, weather resistance, and low maintenance.

At Sui Generis, we specialise in bespoke GRP and FRP composite mouldings and components, offering tailored solutions in any shape, size, colour, or finish — from functional industrial parts to standout visual features. Whatever your vision, we’ll help you bring it to life with a durable and high-quality composite solution.

5 Reasons to Choose Sui Generis Bespoke GRP or FRP Components

- ECONOMY – Cost-effective solutions with long-term value

- QUALITY – Weatherproof, impact-resistant, and built to last

- DESIGN – Manufactured to your unique specification

- LONGEVITY – Exceptional durability with minimal maintenance

- SERVICE – 90% repeat customer rate and trusted expertise