FRP Walkway Systems Engineered for Safety, Durability and Performance

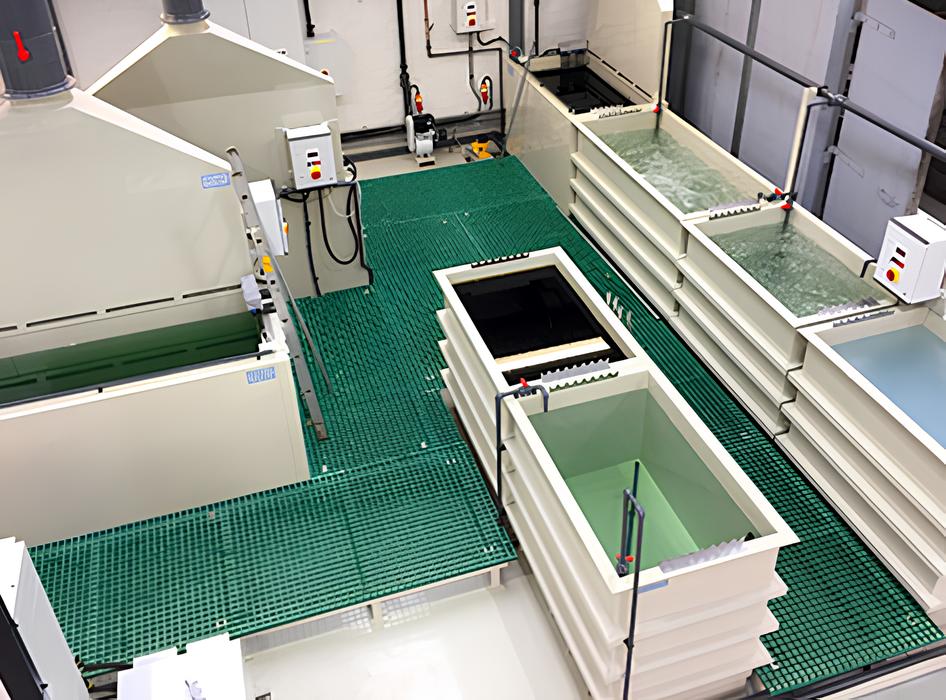

Sui Generis FRP walkways are designed to provide safe, durable, and maintenance-free access across rooftops, industrial sites, and hazardous environments. Manufactured from high-strength Fibre Reinforced Polymer (FRP), our composite walkways deliver excellent slip resistance and load-bearing performance while remaining lightweight and easy to install. Unlike traditional materials, both GRP and FRP is non-corrosive, non-conductive, and resistant to weather, chemicals, and moisture—making it the ideal choice for demanding sectors such as utilities, marine, manufacturing, and rooftop maintenance.

Each GRP walkway system is custom-built to meet your specific site requirements, with a range of options including upstands, kick plates, safety handrails, and integration with platforms or step-over units. Our walkways are fully compliant with UK health and safety standards and are designed to minimise downtime, reduce lifecycle costs, and enhance operational safety. Whether you’re improving access, protecting assets, or meeting regulatory obligations, Sui Generis FRP walkways provide a reliable, long-term solution.

All our GRP/FRP products are proudly manufactured in the UK. This ensures consistent quality control, faster lead times, and full compliance with British standards — supporting local industry and reducing carbon emissions through localised production.

Our FRP walkways are designed to outlast traditional materials such as steel or timber, with none of the maintenance or environmental drawbacks. They are corrosion-resistant, non-conductive, and fully recyclable at end-of-life.

Every walkway panel includes an integral anti-slip gritted surface — ideal for high-risk environments and outdoor areas where slip prevention is essential. GRP is also fire-retardant and non-sparking, offering added safety for industrial and commercial use.

We work closely with you to manufacture custom FRP walkway systems, tailored precisely to your project specifications. Whether it’s size, colour, load-bearing needs or chemical resistance — we deliver purpose-built solutions for your site.

Typical GRP Walkway Applications

- Rooftop access and service walkways

- Industrial flooring and safe access zones

- Marine and offshore platforms

- Footbridges and public infrastructure

- Water treatment plants and chemical facilities

- Railway crossings and trackside maintenance

Frequently Asked Questions (FAQs) About GRP Walkways

Related Products