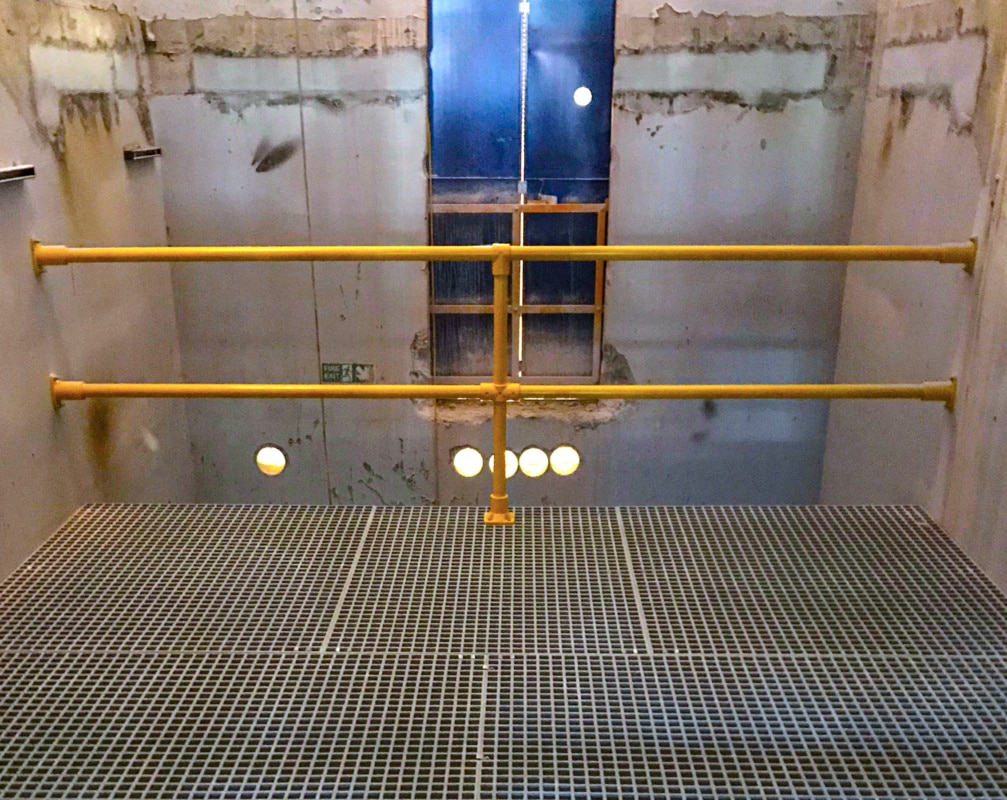

FRP Riser Flooring and Installation

Our FRP Riser Flooring systems provide a safe, durable, and low-maintenance solution for managing open riser voids in commercial, residential, and industrial buildings. Designed for both new builds and refurbishments, our riser systems offer exceptional strength, slip resistance, and adaptability, ensuring full compliance with health and safety regulations.

These systems are ideal for protecting personnel from fall risks during construction and throughout the building lifecycle. With our expert in-house design, fabrication, and installation teams, we provide a complete service, delivering custom-made riser flooring to suit your exact specifications and project requirements anywhere in the UK.

Why Choose FRP for Riser Void Flooring?

Our FRP riser flooring is manufactured using moulded fibreglass grating—a one-piece composite structure made from a high-performance resin matrix reinforced with fibreglass. This process gives it superior mechanical strength, exceptional corrosion resistance, and bi-directional load-bearing capability, meaning that cut-outs for pipes or cables won’t compromise panel integrity.

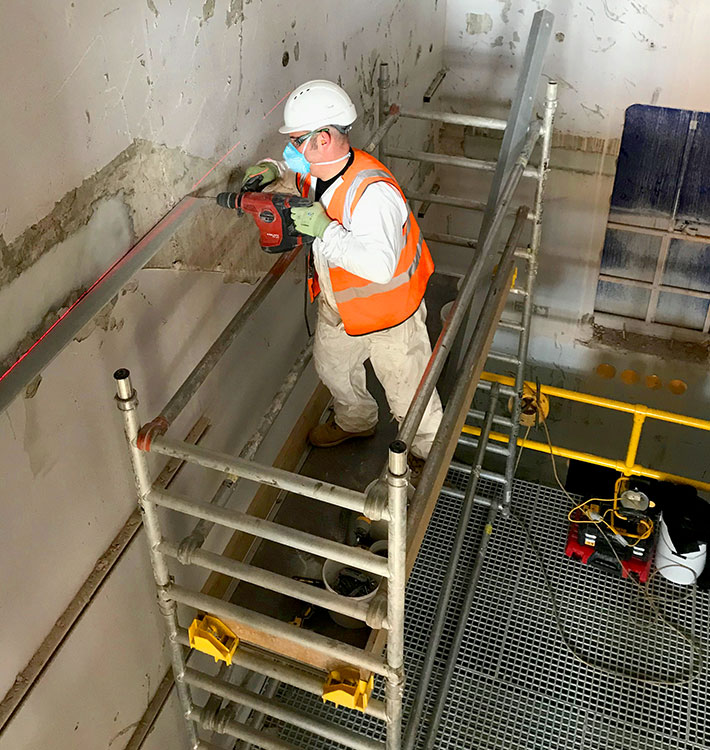

Unlike traditional materials such as steel, FRP is up to 80% lighter, allowing for faster, safer installation with minimal manual handling or heavy lifting equipment. Panels can be cut on-site using standard power tools, with no need for hot works, reducing risk and improving on-site efficiency.

Each panel is finished with an aggressive quartz-gritted anti-slip surface, making our riser flooring an ideal choice for high-risk environments and wet conditions. The non-slip finish dramatically reduces the risk of slips, trips, and falls during construction and ongoing building maintenance.

Supporting Safer Construction and Long-Term Performance

Safety is at the heart of every Sui Generis riser solution. Our systems are designed not just for structural integrity, but for everyday usability and workforce protection. Riser voids are a well-known hazard on construction sites; our FRP flooring helps eliminate fall risks by providing strong, stable, and clearly defined walking surfaces.

Thanks to the material’s non-conductive, non-sparking, and fire-resistant properties, FRP is well suited to a wide range of environments, from high-rise residential to industrial plant rooms. It can be cast directly into the concrete slab, supported on rebated ledges, fixed using FRP angles, or installed on FRP I-beam cross members, depending on your project design.

Design, Fabrication and Installation Services

Our in-house team offers full CAD design and technical support, ensuring your service riser system is manufactured to precise measurements and tailored perfectly to your site requirements. All FRP grating panels are cut to size at our UK-based manufacturing facility, with easy on-site adjustment possible using basic hand tools—no specialist equipment or hot works required.

- Bespoke CAD Design – Every project is modelled in detail to ensure accurate fit, optimal layout, and integration with surrounding structures or services.

- UK-Based Precision Fabrication – Panels are pre-cut at our Essex facility for quality control and faster installation on-site.

- Simplified On-Site Adjustments – Should modifications be needed, FRP can be trimmed easily using standard power tools like jigsaws or angle grinders.

- Seamless Project Support – Our technical team is on hand throughout, from initial enquiry and design through to delivery and installation advice.

Our specialist installation teams are fully certified and highly experienced in fitting FRP riser systems across a diverse range of project types and site environments. From new developments to complex refurbishments, we ensure every installation is completed professionally, efficiently, and with a strong focus on safety and compliance.

- Versatile Installation Methods – FRP riser flooring can be installed in multiple ways depending on site design, including casting into concrete slabs, using support rebates, or fixing directly into the riser void.

- Fully Certified Installers – Our teams hold key health and safety accreditations, ensuring compliance with UK construction standards and safe working practices on every project.

- Tailored to Site Conditions – We assess access, loading, and surrounding infrastructure to determine the best installation method for your riser layout.

- Nationwide Coverage – We deliver and install FRP riser systems across the UK, maintaining consistent quality and service regardless of project size or location.

Available FRP Grating Options

We can accommodate virtually any service riser opening, thanks to a wide range of FRP grating panel sizes that can be easily joined together using secure fixing clips to cover the required area. To support your riser flooring installation, we offer two primary types of FRP grating—each selected based on your project requirements, application needs, and personal preference.

Standard Mesh Grating

- Panel sizes: 1985 x 996mm, 3010 x 996mm or 3660 x 1220mm

- Thickness: 25mm, 38mm, or 50mm

- Colours: Green (RAL 6029), Grey (RAL 7035), Yellow (RAL 1003), or custom colours (extended lead times)

Mini-Mesh Grating

- Panel sizes: 2007 x 1007mm or 4047 x 1007mm

- Thickness: 30mm

- Colours: Grey (RAL 7035) or custom options

Health and Safety Accreditations

Our team holds a comprehensive range of safety certifications, including:

- CSCS, SSSTS, and CITB Health & Safety Awareness

- Confined Space Training (City & Guilds)

- PASMA, IPAF, and WAH Harness, Ladders, Access Towers Training

- EUSR National Water Hygiene

- Asbestos Awareness

- ECITB Safety Passport

- Emergency First Aid

- Safetymen – Safe Use of Abrasive Wheels, IPAF Operator Training & Portable Power Tools

Key Benefits of FRP Riser Flooring

- Provides a safe, non-slip surface to eliminate fall risks

- Maintains structural integrity even after cut-outs for services

- Lightweight and easy to handle on site

- Rapid installation with no hot works required

- Fire retardant and non-conductive for increased safety

- Resistant to corrosion, UV, impact, and chemicals

- Maintenance-free with a 20+ year lifespan

- Custom-made to suit any riser opening size

- Manufactured in the UK with sustainable methods