The UK’s infrastructure is at a crossroads. With the dual challenge of achieving net zero and upgrading ageing assets, the demand for materials that combine durability, sustainability, and cost-efficiency has never been higher. For decades, steel has dominated the landscape — but it is no longer the only option. Increasingly, Glass Reinforced Polymer (GRP) is emerging as the smarter choice.

At Sui Generis, we see this shift happening every day. From refurbishing industrial tanks to manufacturing large-scale composite panels for Network Rail’s FLOW bridge, we’ve proven how GRP delivers long-lasting value where steel falls short.

A Material on the Rise

GRP isn’t new — but its role in infrastructure is changing. According to Composites UK, global demand for composites is set to grow steadily through 2030, with infrastructure and construction among the leading drivers. This reflects what we see in the market: clients in rail, utilities, marine, defence and energy are moving away from traditional materials in favour of lighter, stronger, and more resilient composites.

The reasons are clear. GRP combines structural strength with reduced weight, cutting transport emissions and simplifying installation. Because panels can often be hand lifted or installed with lighter equipment, fewer emissions are generated compared with using heavy lifting machinery. Its corrosion resistance means it continues to perform in aggressive environments where steel fails, from coastal walkways to effluent tanks. And with minimal maintenance requirements, GRP delivers performance measured in decades, not years.

Why GRP Outperforms Steel on Sustainability

Steel has long been the default, but its weaknesses are increasingly unsustainable: corrosion, conductivity, weight, and the high cost of upkeep. GRP addresses all of these challenges directly.

- Weight and transport: GRP is up to 75% lighter than steel, reducing embodied carbon in logistics and foundation works. According to Composites UK, this weight saving can cut transport-related CO₂ emissions by as much as 30% compared with equivalent steel structures.

- Durability: Where steel corrodes, GRP offers 25+ years of reliable service with minimal maintenance. Fewer repair cycles mean fewer carbon-intensive interventions.

- Safety: Non-conductive and thermally insulating, GRP improves safety in rail, utilities, and energy environments. Anti-slip finishes add further protection.

- Lifecycle cost: While upfront costs can be higher, life cycle assessments show GRP can outperform steel and even concrete over long service lives (80–100+ years), particularly in harsh climates. Independent studies also show GRP elements can reduce total embodied carbon by 20–35% compared with steel when assessed over full lifecycle performance.

Climate Matters: How GRP, Steel and Concrete Compare

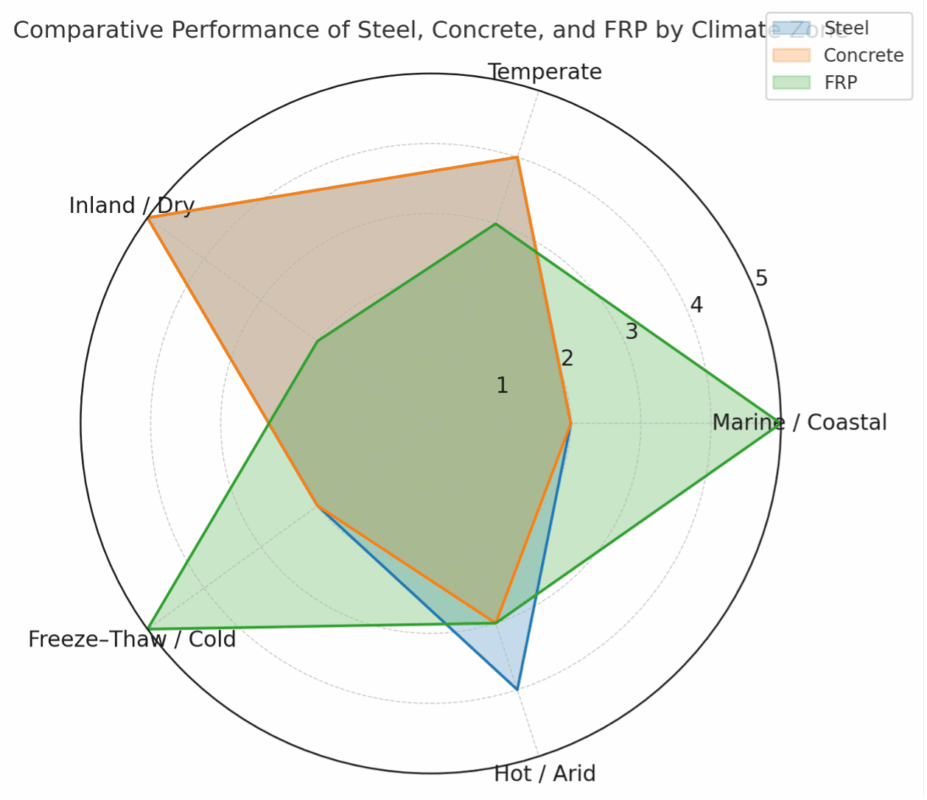

Independent studies highlight that performance and sustainability are heavily dependent on climate conditions:

- Marine/Coastal: Steel suffers corrosion, concrete reinforcement degrades, while GRP’s corrosion resistance makes it the most sustainable choice.

- Freeze–Thaw / Cold: GRP avoids freeze–thaw cracking and chloride scaling, outperforming steel and concrete in durability and carbon efficiency.

- Inland/Dry: Steel and concrete remain competitive, but GRP can still deliver advantages where weight and modularity reduce emissions.

- Hot/Arid: With UV protection, GRP maintains performance while reducing maintenance compared to steel and concrete.

To illustrate, the radar chart below compares the relative performance of steel, concrete, and FRP (GRP/FRP) across different climate zones, based on durability, maintenance demand, and long-term carbon footprint:

Across all environments, the hidden sustainability cost of maintenance is decisive. Every repair to steel or concrete adds embodied carbon, whereas GRP’s low-maintenance profile minimises lifetime emissions. Studies show GRP can reduce embodied carbon by up to 30% compared with steel, and when combined with transport and installation efficiencies, the savings can be even greater.

Proven in Practice

Our projects demonstrate these advantages in real-world settings, from landmark case studies to everyday infrastructure applications:

- Bridges & Walkways – Lightweight GRP decks, platforms, and risers replace heavy steel or concrete, reducing transport emissions and corrosion risks.

CASE STUDY: Network Rail’s Innovative FLOW Bridge

- Tank Covers & Linings – Corrosion-resistant GRP protects critical assets, extending service life and avoiding carbon-heavy replacements.

CASE STUDY: St Pancras International Station Refurbishment

- Trench & Access Covers – Strong yet lightweight alternatives to concrete or steel, simplifying installation and lowering lifetime maintenance.

- Enclosures & Housings – Secure, weatherproof GRP cabinets safeguard equipment in demanding environments.

CASE STUDY: FRP Enclosures for £60 million state-of-the-art blood centre in Filton, Bristol

- Ladders, Stairs & Access Systems – Non-conductive, anti-slip GRP improves safety in rail, utilities, and energy settings.

- Rail & Utility Structures – GRP gratings, platforms, and troughs deliver durable, low-maintenance performance where timber or concrete would fail.

Building for a Net Zero Future

The growth of GRP reflects a broader industry shift towards lifecycle thinking. Its lightweight nature reduces transport emissions. Its durability reduces replacement cycles. And when used in refurbishment, it extends the life of existing assets without the embodied carbon of full replacement.

Research and development into recycling is advancing, opening the door for GRP to contribute more strongly to a circular economy. Meanwhile, steel recycling and concrete downcycling continue to improve, ensuring each material has a role in sustainable infrastructure — but for many applications, GRP is already the standout performer.

The Sui Generis Difference

At Sui Generis, we combine technical expertise with a commitment to sustainability, delivering GRP solutions that protect assets, improve safety, and reduce costs over their lifecycle. Whether designing bespoke enclosures, lining tanks, or supporting major infrastructure schemes, our focus is the same: to engineer solutions that last.

Infrastructure that is fit for the future cannot rely on materials of the past. With GRP, and with partners like Sui Generis, the industry has a proven material that can meet today’s demands — and tomorrow’s challenges.

References

1. Jena, S.D. & Kaewunruen, S. (2021). Life Cycle Sustainability Assessments of an Innovative FRP Composite Footbridge. Sustainability, 13(23), 13000.

2. Frontiers in Built Environment (2023). Comparative life cycle assessment of GFRP, CFRP and steel bars in harsh environments.

3. Malmgren, L. (2014). Comparative study of different bridge concepts: life cycle assessment and life cycle cost analysis. Chalmers University of Technology.

4. Basalt Engineering (2024). Sustainability of alternative reinforcement for concrete structures – LCA of Basalt FRP bars.

5. Composites UK (2023). Boom in GRP market spurs innovation and capacity expansion.