The client – Ameycespa (East) Ltd

Ameycespa (East) Limited is a waste management company offering a comprehensive range of waste and recycling services to businesses, local authorities, schools and colleges, health and social care services and householders.

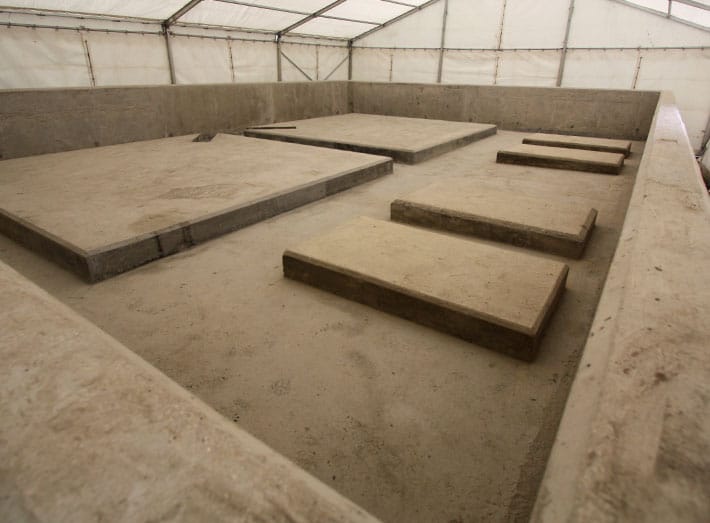

1. Existing ammonia sulphate tanks and concrete bund.

The problems – chemical damage to existing bunds

Ameycespa had two internal chemical tank bunds holding sulphuric acid and a ‘scrubber tank’ in which chemicals were mixed. Over the two years the tanks had been in operation damage had occurred to the concrete bund floor in the chemical storage area.

2. Acid tank bund prior to surface preparation by our specialist lining team.

New exterior tank bunds to be lined on a tight deadline

In addition, the company had two newly-built external bunds that needed lining with fibreglass before tanks were to be installed. The work needed to be done quickly – tanks were due to arrive from Spain, so the storage tank bund had to be ready.

3. Surface preparation and cleaning and removal of debris of the tank bund prior to glass fibre lamination.

The solution – chemical tank bund repair and fibreglass lining

We grit blasted the internal chemical tank bunds to remove debris and then made minor but necessary repairs. Next we applied a high-quality vinyl ester resin using a four-coat system able to protect against 76% concentrations of sulphuric acid – good environmental practice.

A protective tent was erected over the external bunds, allowing us to work in all weathers and meet the important deadline. We were then able to apply chemical resistant fibreglass lining to the two new concrete bunds.

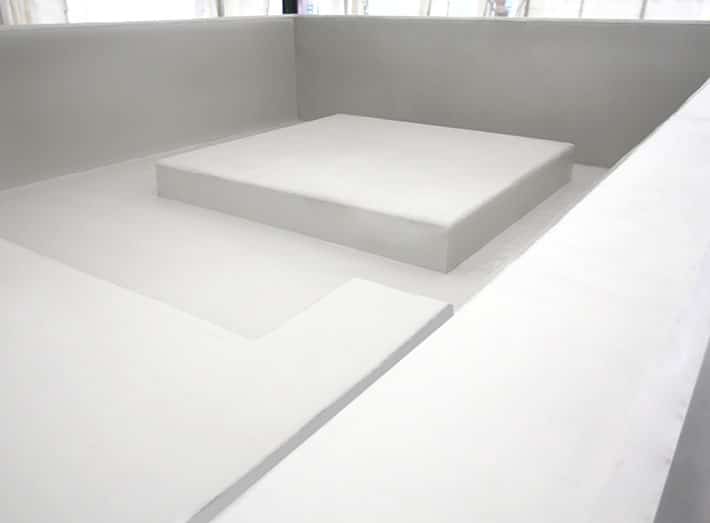

4. Completed area, GRP lining of tank bund, walls and floor.

The result – watertight bunded areas, on schedule

We were able to work quickly, applying top-quality fibreglass linings to meet the deadline.

Wayne Surry, Site Supervisor, Sui Generis, says:

“Whilst making good the existing bunds, it was a great opportunity to line the new bunds, ensuring they benefited from a long-term, maintenance free lining from the outset.”

5. A new concrete tank bund before GRP lining system applied.

Tank bund lining solutions

We offer a high quality bund lining service to produce a simple, long term cost effective solution to your spill containment, protection and corrosion problems.

6. GRP lining applied, ready for top coats.

Get a FREE site survey today

Our technical surveyors have years of experience within the industry and are experts in fibreglass lining.

A free site survey will provide you with recommendations for the future use of your tank bund spill containment area.

Call our specialist team to discuss your requirements, quote and get a FREE site survey: 01206 798 798.

7. After, showing completed bunded areas GRP lined with top coats.

8. Before, concrete tank bund ready for GRP lining.

9. After, showing completed bund area with GRP lining.

10. Before, tank bund area, ready for fibreglass laminate application.

11. After, completed acid tank bund GRP lining with final top coats.

12. Before, showing the new concrete bunded area.

13. After, showing completed fibreglass lined bund walls, gullies and sumps. Ready for tank installation.