How Sui Generis Restored a Corroded Effluent Storage Tank with GRP Lining

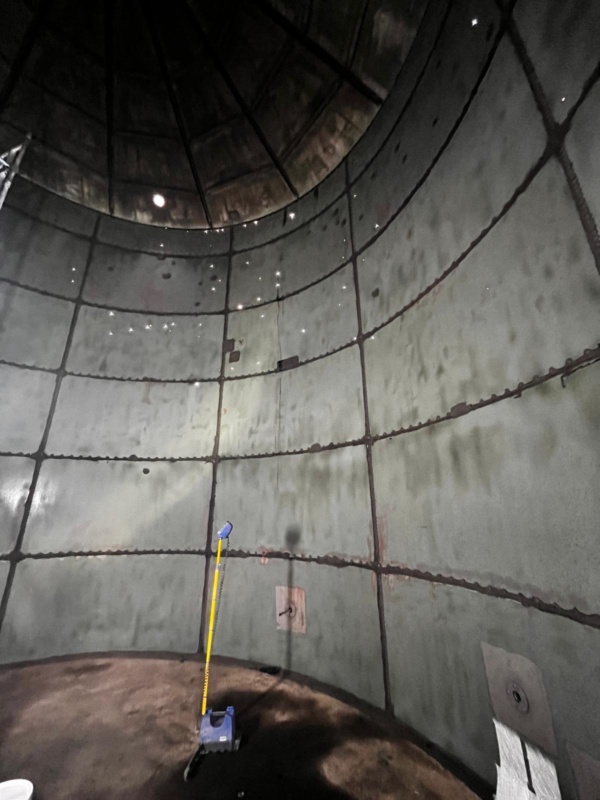

Sui Generis International was commissioned by a leading UK tank engineering contractor to deliver a full industrial GRP tank refurbishment for one of two effluent storage vessels at a major industrial facility. Acting on behalf of the site’s operations company, our team provided a comprehensive tank lining solution to extend the operational life of a sectional-type effluent tank showing significant signs of corrosion.

This project demonstrates our ability to repair and protect ageing industrial tanks, delivering long-lasting corrosion protection using our glass-reinforced polymer (GRP) lining systems.

Project Outcomes

- Extended tank lifespan by decades with a robust GRP lining system

- Full corrosion protection for both walls and floor against aggressive effluent

- Improved inspection capability with a smooth, pigmented internal surface

- No operational delays — works delivered on schedule and within budget

The Challenge

Sectional-type tanks are widely used across the UK in water treatment works and effluent processing facilities due to their glass-fused steel construction. However, after 10-15 years of service, corrosion through the internal coating can potentially occur if the tank is poorly constructed or maintained, especially in aggressive effluent environments.

In this case, the most severe corrosion was found above the water line, creating a risk to the vessel’s long-term integrity. Our task was to provide a cost-effective effluent tank repair that would restore full functionality and ensure ongoing compliance with safety and operational standards.

Safe Access and Surface Preparation

Before our arrival, the tank was fully cleaned by others, and a panel was removed by the main contractor to provide safe and efficient access. This step not only improved site safety but also enhanced ventilation during the lining works.

To achieve optimal adhesion and to create a profile to gain adherence, all steel wall and concrete floor surfaces were grit blasted to remove contamination, corrosion, and residual coatings.

Where the tank shell exhibited through-corrosion, we applied a resin primer to seal the affected areas, reinforced with 600g/m² glass fibre matting impregnated with the specified resin, and in the case of larger holes, applied multiple matting layers to ensure a structurally sound repair.

GRP Tank Lining Application

Before the main wall lining began, strips of 600g/m² matting were applied to all bolts and seams, impregnated with resin to provide additional reinforcement and ensure these high-stress areas were fully sealed.

Our tank lining process then involved several precision steps. For the wall lining, full-length 600g/m² matting sections (2.0–2.4m) were hung onto resin-prepared surfaces, fully impregnated from the outer surface using handheld rollers, and covered with a tissue veil before curing to enhance chemical resistance and ensure a pinhole-free finish. This process was repeated in 1-metre-wide drops until the full tank wall was lined.

For the floor lining, 600g/m² matting was laid across the floor, soaked and emulsified to remove air pockets and pinholes, and followed by a pigmented resin coat for enhanced durability and inspection visibility.

Finishing and Quality Assurance

After curing, any irregularities were sanded to create a smooth finish. The tank was given a final clean before a waxed topcoat was applied for long-term protection.

The removed panel was reinstalled by the main contractor, and our team sealed the join using the same GRP lining method to ensure 100% continuity in the corrosion barrier.

The project was completed on time and to specification, with a full client sign-off upon final inspection.

Benefits of Lining Repair vs Complete Tank Replacement

Opting for a GRP lining repair instead of a full tank replacement offers significant advantages for industrial sites. Lining repairs can be completed in a fraction of the time required for replacement, minimising downtime and disruption to operations. They are also far more cost-effective, often achieving savings of 50% or more compared to installing a new tank.

By refurbishing the existing structure, businesses can avoid the logistical challenges of tank removal, disposal, and reinstallation, while also reducing environmental impact through reuse of the original vessel. Additionally, a GRP lining provides a seamless, corrosion-resistant barrier that often outperforms the original factory coating, extending service life for decades.